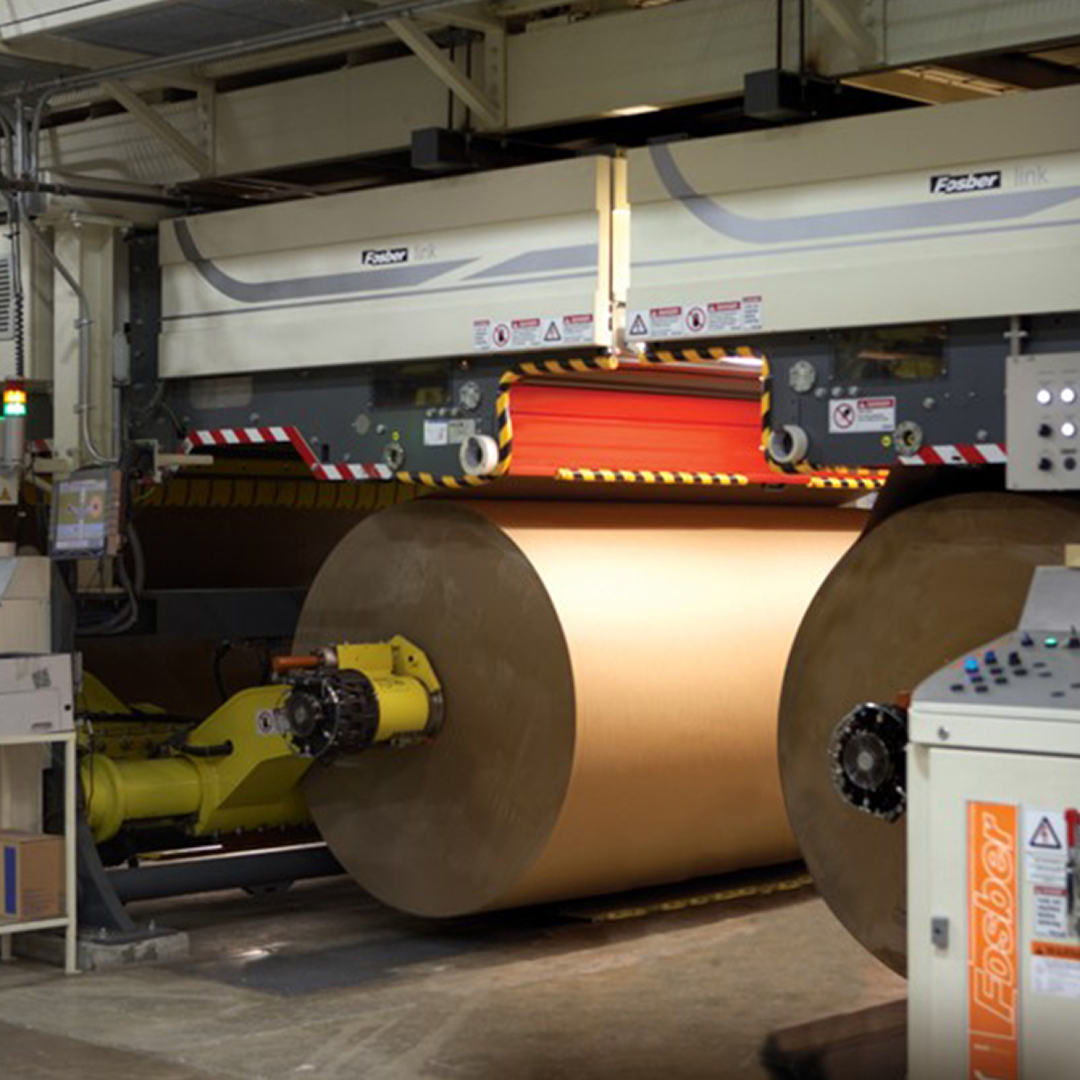

A corrugator is a high-speed industrial machine used to manufacture corrugated board, which is then converted into boxes and packaging materials. It operates by bonding multiple layers of paper together, forming fluted (wavy) layers that enhance strength and durability. State of the art automatic box manufacturing machines.able to run 23”-82”wide rolls.

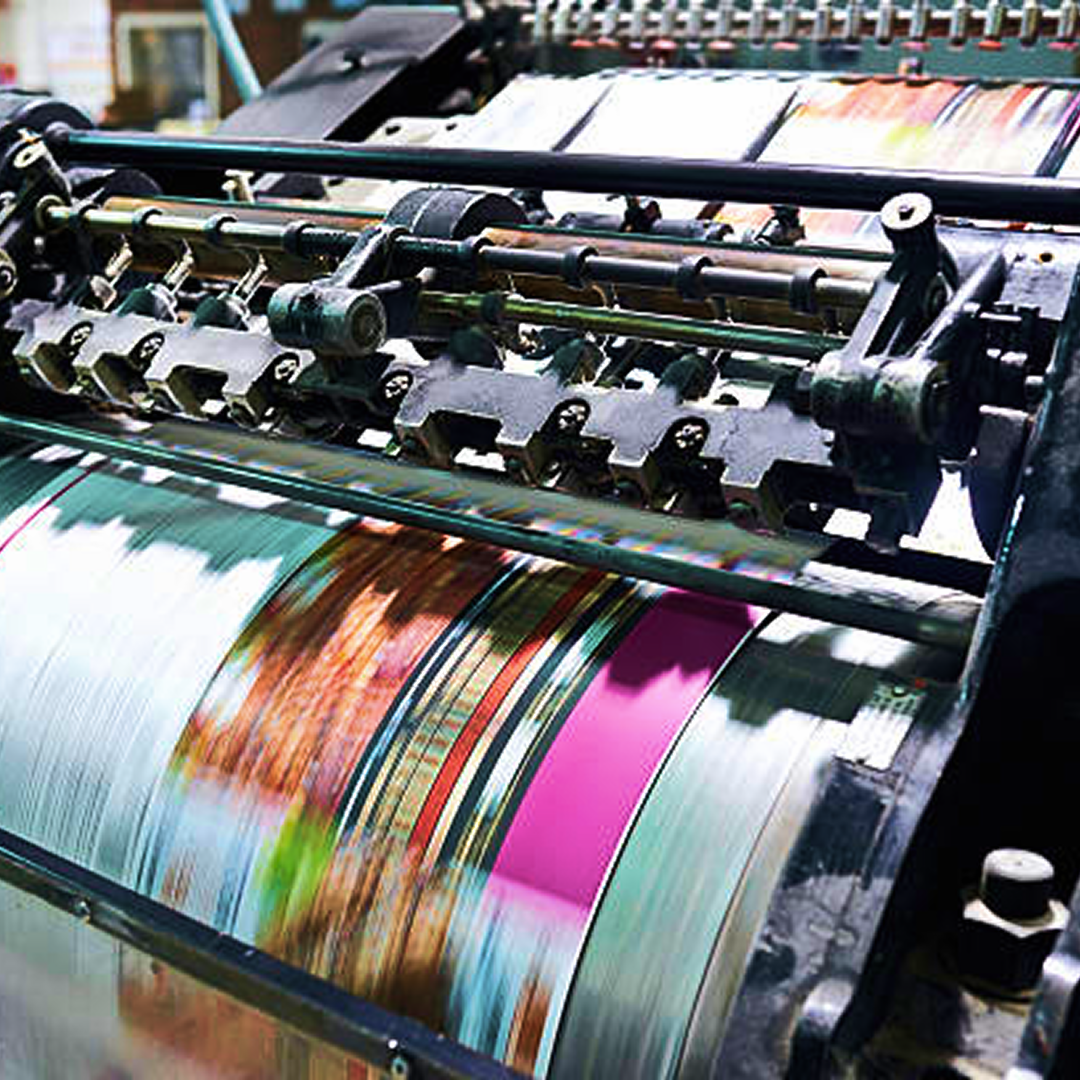

Our company specializes in high-quality box printing, delivering precision, durability, and vibrant designs for all packaging needs. Using advanced printing technology, we offer custom branding solutions, ensuring your boxes stand out with sharp graphics and long-lasting prints. We print on single-wall (C, B, D, E) and double-wall (BC, BD, ED) corrugated boxes, maintaining excellent color accuracy and consistency. From small cartons to large industrial packaging, we accommodate various sizes and custom requirements.

Die cutting is a precision manufacturing process used to cut, shape, and perforate materials like corrugated boards, cardboard, and paper into specific designs. It ensures uniformity and efficiency in box production, allowing for custom shapes, slots, and folds essential for packaging, branding, and structural integrity.

At JSH Packagings, we provide premium finishing and specialty services to enhance the quality,

durability, and visual appeal of your packaging. Our advanced finishing techniques ensure that

your brand stands out while offering superior protection and functionality.

Stitching machine: Joints that require staples instead of glue, this machine can do medium to

jumbo

sizes, including 1-piece and 2-piece stitch work. TAPER/GLUER: Glue/tape and fold center glued

cartons,

die cut cartons, and regular cartons

"At JSH Packagings, we take quality control seriously. Our fully equipped lab

allows us to monitor and maintain

the highest standards at every stage of production. We utilize state-of-the-art testing equipment to

ensure

the

durability, reliability, and precision of our products.

Here’s a look at the key testing machines we use in our facility: "

It measures the weight and thickness of materials, ensuring uniformity and consistency. This is crucial for maintaining quality.

This machine evaluates the strength of materials by applying hydraulic pressure until the sample bursts. It helps in determining the durability of packaging materials

Controlling moisture content is essential to prevent product deterioration. It accurately measures moisture levels, ensuring performance and longevity of materials.

It measures the water absorption capacity of paper, cardboard, and similar materials. It helps in assessing the resistance of packaging materials to moisture.

Used to determine the compressive strength of materials, this machine plays a critical role in testing packaging boxes, cartons,other products.

"JSH Packagings brings you the best product quality in the market"

| Equipment | Quantity |

|---|---|

| Five ply automatic box manufacturing plant | 62" and 82" |

| Paper Board Cutters | 15 |

| Pasting Machines | 12 |

| Rotary Machine | 10 |

| Pasting and Slot Cutting Machine | 8 |

| Die Cutting Machines | 21 |

| High Speed Corrugation M/c | 08 |

| Automatic Stitching Machine | 02 |

| Auto Gluer | 01 |

| Stitching Machine | 32 |

| Lamination Machine | 02 |

| Board Printer | 02 |

Stay Up to Date

Be the first to discover our latest packaging solutions, design innovations, and industry

insights. Subscribe to our newsletter and never miss an update—no more Fear of Missing Out!

Ready to transform your packaging and create a lasting impression? Contact us today to discuss

your needs, request a quote, or explore how our customized packaging solutions can add value to

your products. Let’s work together to make your brand stand out!